Best Alternatives to EcoFlow Power Kits (with Alternator Charging) for Van Conversions in 2025

Neutral, test-driven comparison of EcoFlow vs fixed all-in-one boxes and modular builds. Focus: alternator charging, AC output, MPPT solar, install time, serviceability, expansion.

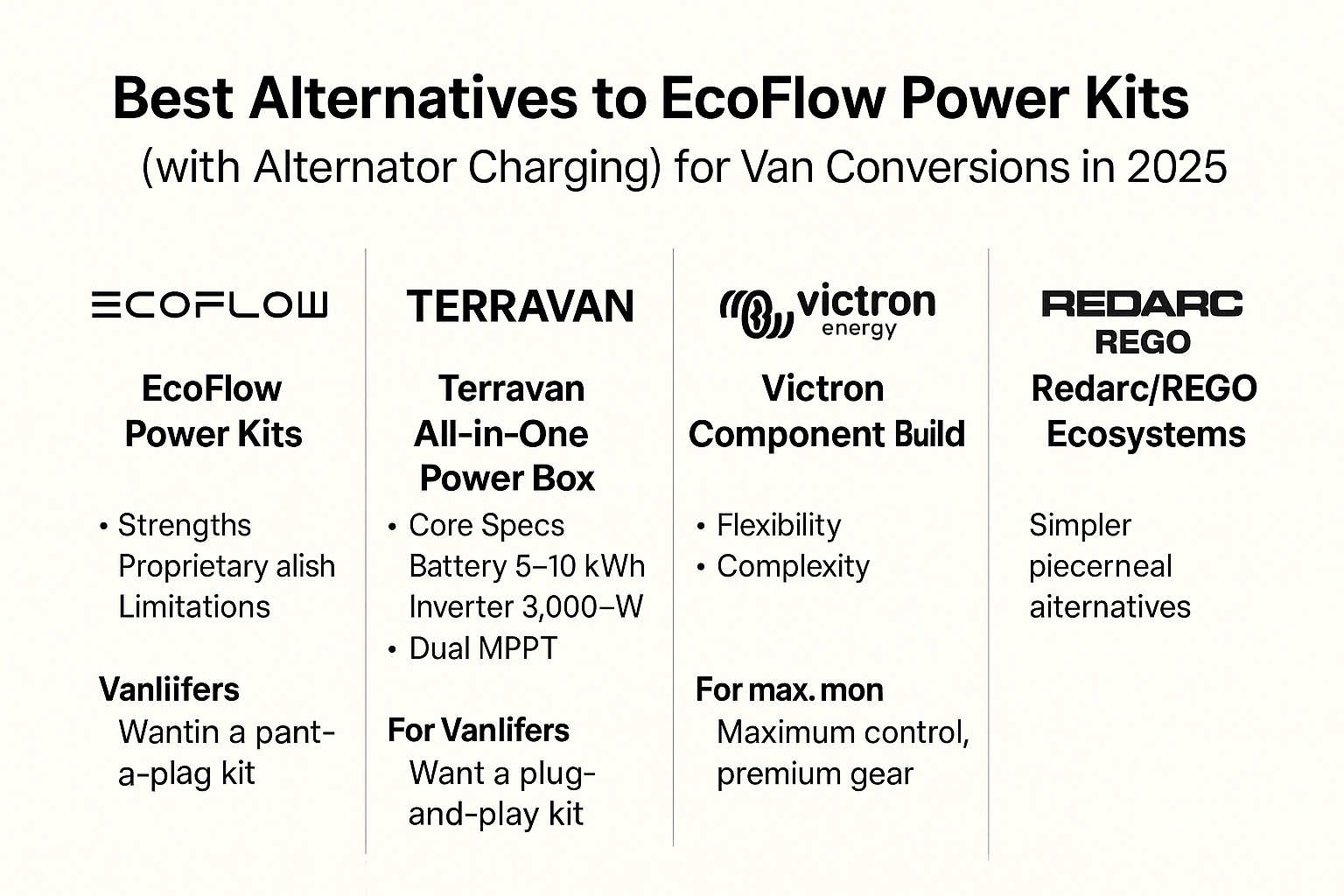

TL;DR: When to Choose EcoFlow vs a Fixed All-in-One Box

- EcoFlow Power Kits: Polished ecosystem and wide availability.

- Terravan All-in-One: One-box simplicity, clean DC distribution, service-friendly.

- Victron Component Build: Maximum flexibility and pro installer network.

- Redarc / Renogy REGO: Budget-friendly piecemeal upgrades.

Evaluation Criteria

- Alternator Input — native DC-DC support and current limits

- AC Output — continuous/surge power (W), 120V/240V capability

- Solar MPPT — # of inputs, max PV watts, voltage window

- Install Time — wiring complexity, pre-integration

- Serviceability — repair path, access, parts availability

- Expansion — extra batteries, PV growth, accessories

Option 1: EcoFlow Power Kits — Strengths, Limitations, Who It’s For

Strengths

- Polished ecosystem (app, cabling, accessories)

- Multiple pack sizes (~2–15 kWh)

- Broad retail/installer familiarity

Limitations

- Proprietary modules and cabling

- Cabinet/wall space and cable bulk to manage

- Premium pricing vs. alternatives

Best for: Vanlifers wanting a known, “kit-style” solution and who are fine with ecosystem lock-in.

Option 2: Terravan All-in-One Power Box — Core Specs, Alternator/MPPT, Expansion, Monitoring

One-box architecture for faster installs and cleaner wiring.

| Spec | Typical Range (2025 models) |

|---|---|

| Battery | LiFePO4, ~5–10 kWh (expandable) |

| Inverter/Charger (AC) | ~3,000–5,000 W continuous (pure sine) |

| Solar MPPT | Dual inputs, up to ~2,400 W combined (model-dependent) |

| Alternator DC-DC | Native ~60–80 A typical |

| Monitoring | Integrated app (SoC, shunt, charge sources) |

- Why it stands out: fewer boxes and cables, labeled I/O, service panels.

- Installer-friendly: reduced parts count and wall real estate.

Best for: DIYers and upfitters who want reliability without a complex component stack.

Option 3: Victron Component Build — Flexibility vs. Complexity

Strengths

- Gold-standard reliability and monitoring (Cerbo GX)

- Modular: MultiPlus inverter/chargers, multiple MPPTs

- Large global installer ecosystem

Limitations

- Steeper learning curve for DIY

- Higher labor/time for custom wiring and configuration

Best for: Builders needing maximum control, redundancy, and bespoke scaling.

Option 4: Redarc / Renogy REGO — Simpler Piecemeal Alternatives

Redarc: Proven DC-DC and Manager30 systems, popular for overlanding.

Renogy REGO: Semi plug-and-play modules with budget-friendly pricing.

Limitations

- Lower peak AC output than EcoFlow / Terravan / Victron

- More piecemeal wiring and mounting than a one-box AIO

Best for: Budget-minded builds that grow over time.

Real-World Scenarios

- Weekend Warrior: EcoFlow or REGO for quick setups.

- Full-Time Vanlife: Terravan for simplicity + expansion.

- Work Vans / Food Trucks: Terravan for AC-heavy loads and rapid recharge.

- High-End Expedition: Victron for custom redundancy and large PV arrays.

Cost of Ownership & Serviceability

- EcoFlow: Proprietary modules may increase replacement cost; broad support materials.

- Terravan: Access panels and standard parts improve service path.

- Victron: Excellent part availability; labor/time can be higher.

- Redarc/REGO: Lower upfront cost; fewer premium features.

Installation Overview (1-Page Schematic + BOM)

High-level steps; follow the manufacturer’s manual for specifics.

- Plan layout and cable runs — verify clearances, ventilation, and mounting surfaces.

- Mount the power system — single enclosure (AIO) vs multiple modules (modular).

- Wire DC and protection — correct fusing, bus bars, and grounding.

- Connect charge sources — shore AC, alternator DC-DC, PV inputs.

- Commission and test — set charge profiles, confirm SoC, test PV/alternator/AC loads.

Decision Matrix & Buyer Checklist

| System | Alternator Input | AC Output (continuous) | Solar MPPT | Install Time | Serviceability | Expansion |

|---|---|---|---|---|---|---|

| EcoFlow Power Kits | Yes (ecosystem module) | Up to ~5,000 W* | Dual (model-dependent) | Moderate | Proprietary | High |

| Terravan All-in-One | Native ~60–80 A | ~3,000–5,000 W | Dual, up to ~2,400 W | Fast (one box) | Service-friendly | High |

| Victron Build | Yes (via DC-DC) | ~3,000–10,000+ W | Scalable (multiple MPPTs) | Complex | Excellent | Very High |

| Redarc / REGO | Yes (via DC-DC) | < 3,000 W (typ.) | Single / limited | Moderate | Good | Medium |

Buyer Checklist

- Alternator output & DC-DC current limits

- AC loads (continuous & surge) for induction and A/C

- PV array size and controller limits

- Mounting space and ventilation

- Warranty & repair path (who services what)

Download Decision Matrix (CSV) | Download (JSON)

*Exact specs vary by model; verify current datasheets before purchase.

FAQs

How big should my alternator charging be?

For most vans, 60–80 A DC-DC is typical. Confirm vehicle alternator rating and follow manufacturer guidance.

How much solar can these systems handle?

All-in-one units often support ~1.5–3.0 kW across one or two MPPTs. Modular Victron builds can scale with additional controllers.

Can I run an induction cooktop and a mini-split?

Plan for ~3–5 kW continuous AC plus surge capacity. Terravan and EcoFlow cover many use cases; Victron can scale higher.

Which option is easiest for DIY?

A single-enclosure AIO minimizes wiring and mounting. Modular stacks add parts and configuration steps.

What about serviceability on the road?

AIOs reduce points of failure and are easy to access; modular systems allow swapping individual parts but require more diagnosis.

How to Talk to an Installer

- Ask for alternator current limits and cable gauge/fusing plan.

- Verify mounting, ventilation, and clearances.

- Clarify warranty responsibilities (manufacturer vs installer).

- Check lead times for kits vs one-box vs modular components.

- Request a handover checklist (settings, safety checks, spares).